- Data-Driven AI Algorithms & Machine Learning

Application of machine learning to predict equipment health

- Storage of High-Resolution Data

Rich data points stored for short- and long-term diagnostics and troubleshooting

Encrypted data sent securely to the user cloud for storage

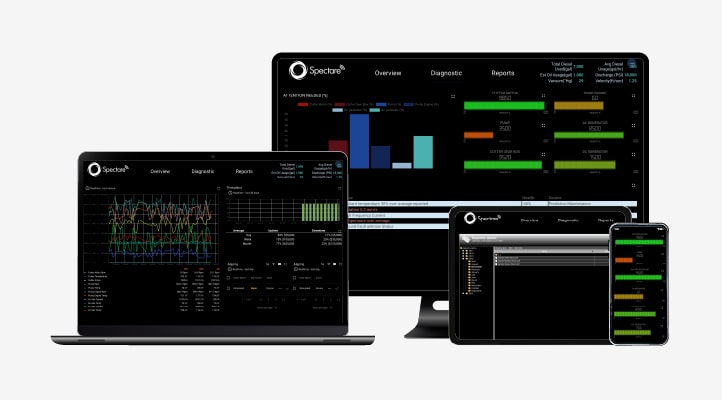

View and manage all assets securely and accurately from a single dashboard by phone, tablet, laptop, or desktop.

Alert the right person at the right time by SMS text and/or email.

View usage costs and determine asset upgrades from real-time operating data and performance analytics.

On-demand access to expert engineers and technicians who have the know-how to quickly troubleshoot, diagnose, and yield solutions.

Al algorithms determine an asset’s condition from real-time and historical data to predict when maintenance should be performed.

AI algorithms identify anomalous behavior and alert operators by SMS text and/or email to take preventative action.

- Field Service Dispatching

Tenured, highly skilled technicians with fully equipped mobile tooling trailers are available around-the-clock for unmatched response times.

AI algorithms provide accurate forecasting of critical spare parts needed prior to failure, when to replace, and quantity to order.

- Service History Management

Upload prior service history records and sync with future service events.

Track location of assets by name, make, model, or description. For mobile machines, optional GPS tracking is available.

.png?width=250&height=252&name=ISS_FAQ(2).png)

.png?width=250&height=252&name=Resized_Thumbnails%20(2).png)