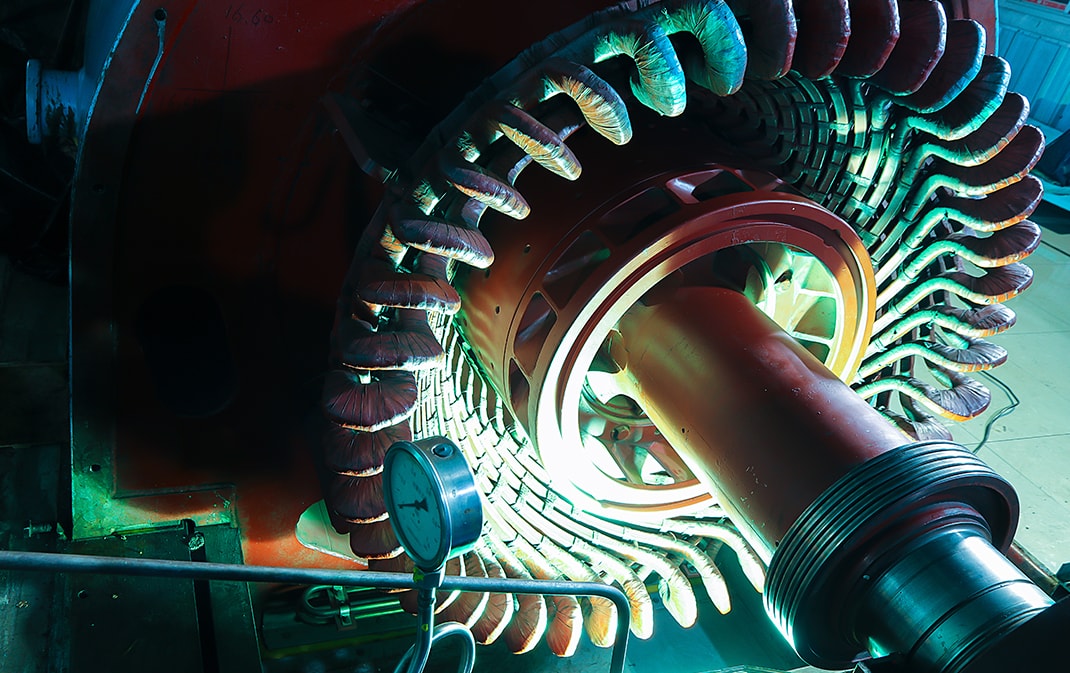

The industrial manufacturing sector operates in an environment of intense competition, necessitating a continual focus on efficiency. Traditional process monitoring methods, while valuable, frequently encounter typical process failures, undermining factory optimization and performance monitoring. The emergence of digital solutions provides innovative mechanisms to counter these challenges. This article will analyze digital solutions and their capacity for industrial transformation.

The Limitations of Traditional Process Monitoring

Traditional process monitoring within industrial manufacturing confronts several difficulties, such as:

- Unanticipated System Downtime: Traditional monitoring techniques sometimes fail to accurately predict system disruptions. This reactive approach to maintenance can lead to unplanned downtime and productivity losses.

- Real-Time Data Blind Spots: In our era of immediate information access, standard monitoring may lack timely updates, providing insufficient insights into current machine status or energy consumption.

This presents a clear necessity for enhanced methods of industrial process monitoring and optimization. Digital solutions, as provided by Industrial Service Solutions (ISS), could be the answer.

Adopting Digital Solutions for Manufacturing Process Optimization

Frequent process disruptions, which can instigate a cascade of system failures, are common in many industrial manufacturing environments. Even minor disruptions can negatively impact factory optimization. However, digital solutions offer a variety of advantages:

- Decreasing Disruptions: Digital solutions can reduce both the frequency and duration of system disruptions, thereby improving overall system efficiency.

- Enhancing System Performance: These solutions can also improve system performance and optimize energy consumption, leading to reduced operating costs.

- Managing Costs and Understanding System Needs: Facilities that have adopted digital solutions, such as those offered by ISS, typically report better control over costs and an improved understanding of their system’s requirements.

- Minimizing Downtime, Improving Safety: A substantial decrease in system downtime and enhanced staff safety are added benefits of implementing digital solutions.

A key player in this digital transformation is the Spectare® Intelligent Platform by ISS. This solution is revolutionizing performance monitoring and providing significant benefits for operational efficiency.

A Step-by-Step Guide to Harnessing the Potential of Real-Time Manufacturing Analytics and Performance Monitoring

Unlocking the potential of real-time manufacturing analytics and performance monitoring requires a strategic approach. Here, we provide a succinct guide to facilitate operational optimization using modern system platforms and digital solutions:

- Utilize Machine Learning Algorithms: Modern platforms decipher complex data sets to provide intelligent insights directly from the systems being monitored.

- Deploy Sensors Across Systems: Sensors continuously supply real-time data to your analytics, creating an accurate and timely overview of operations.

- Understand Optimal Operating Conditions: Use the real-time data to identify optimal system performance parameters and highlight areas for improvement.

- Automate Processes: Implement solutions like ISS’ Spectare® Intelligent Platform to facilitate efficient operations without the need for constant supervision.

- Optimize Manufacturing Processes: Apply real-time monitoring and manufacturing analytics to streamline operations and enhance productivity.

- Embrace Digital Solutions: Transition to digital solutions for a smarter, more efficient approach to industrial manufacturing.

By following these six steps, you can effectively leverage real-time analytics and performance monitoring to enhance operational efficiency and stay competitive in the industrial manufacturing sector.

ISS Spectare®: Advanced Manufacturing Process Optimization

Industrial Service Solutions (ISS) is dedicated to providing advanced solutions for streamlining industrial manufacturing. We have developed an advanced AI-powered platform, which leverages machine-learning capabilities and provides real-time, data-driven insights.

Key features of the ISS Spectare® Intelligent Platform include:

- Real-Time Insights: Spectare® provides real-time insights, smart controls, and predictive modeling to enable improved decision-making.

- Machine Learning Expertise: By harnessing machine learning algorithms, Spectare® optimizes energy usage controls and predicts maintenance requirements, utilizing data from across the system.

- System Optimization: Spectare® enables comprehensive system optimization and an innovative approach to maintenance.

Spectare® in Action: Demonstrated Success

Spectare® assists facility managers in making informed decisions for failure prediction and downtime minimization. It has been successfully deployed in various scenarios, ranging from integrating new electrical components to complete industrial system overhauls.

Spectare®’s scalability makes it a suitable solution for any system, regardless of size, capacity, or variability in data input and energy consumption. A particularly successful application has been within marine dredging operations. Here, the adaptive approach of our platform has proven invaluable due to the dynamic operational environment. With the help of Spectare®, a dredging operator can visualize how changing a single pump or valve setting can improve one metric while potentially limiting another. Consequently, informed decisions can be made to ensure the entire asset operates at peak performance.

The ISS Spectare® Intelligent Platform is setting a new standard for factory optimization and operational efficiency within the realm of digital solutions for industrial manufacturing.

Ready to Capture the Value of Digital Solutions in Process Optimization?

The industrial manufacturing sector is recognizing the transformative power of digital solutions, largely due to intelligent platforms like ISS’ Spectare®. Process optimization has evolved from being a daunting obstacle to an empowering journey.

- Industrial Transformation: Industrial Service Solutions has been a pioneer in industrial optimization, leveraging our dual role as a manufacturer and service provider to offer a holistic approach to digital solutions.

- Error Reduction: Tools such as the Spectare® Intelligent Platform can guide your facility toward peak performance.

- Adaptability: Whether it’s a small-scale facility or the most substantial capacity load testing facility in North America, our engineers and software systems are ready for the challenge.

Connect with our team today to discover how our customized digital solutions can boost your operational efficiency, seamlessly aligning with your setup. With the ISS Spectare® Intelligent Platform, you are well-positioned to navigate toward a streamlined, efficient, and high-performing manufacturing operation.