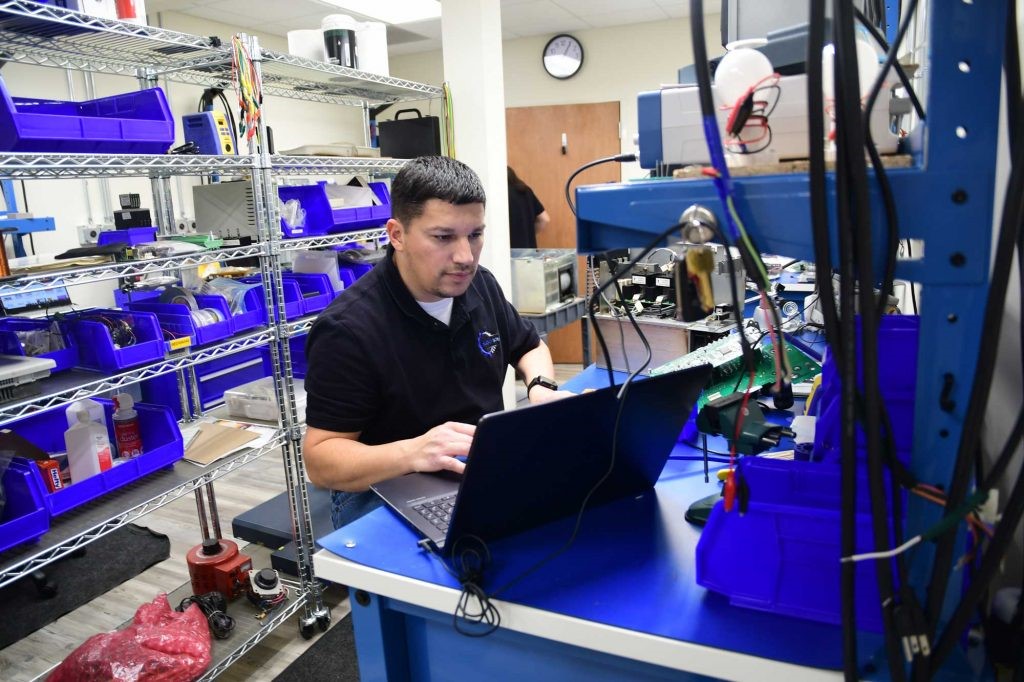

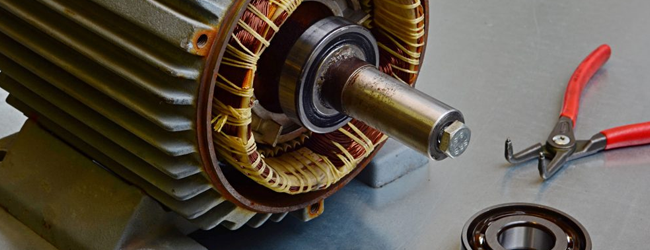

As one of the oldest servo motor repair companies in the United States, ISS OEM-trained technicians use factory data to repair and rebuild servo motors and rotary actuators to original performance specification. From motor remagnetizing to complete disassembly of the feedback, to rewinding, our teams are ready to service every type of servo motor.

- CNC machine tools

- Robots

- Tire & rubber

- Woodworking

- Printing and paper conveying

- Material handling equipment

- Food processing

- Textile equipment

ISS services virtually every feedback system, including AC brushed and brushless motors, DC brushed and brushless motors, steppers, spindle motors, encoders, and resolvers.