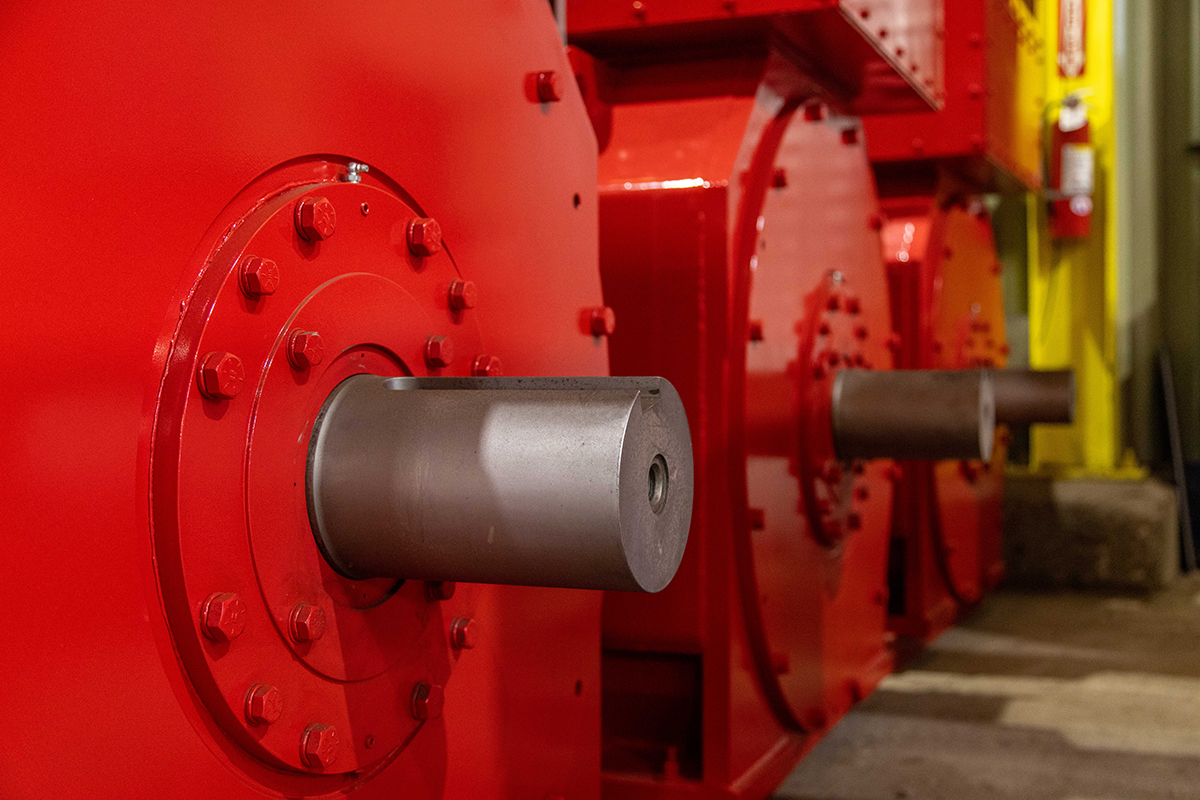

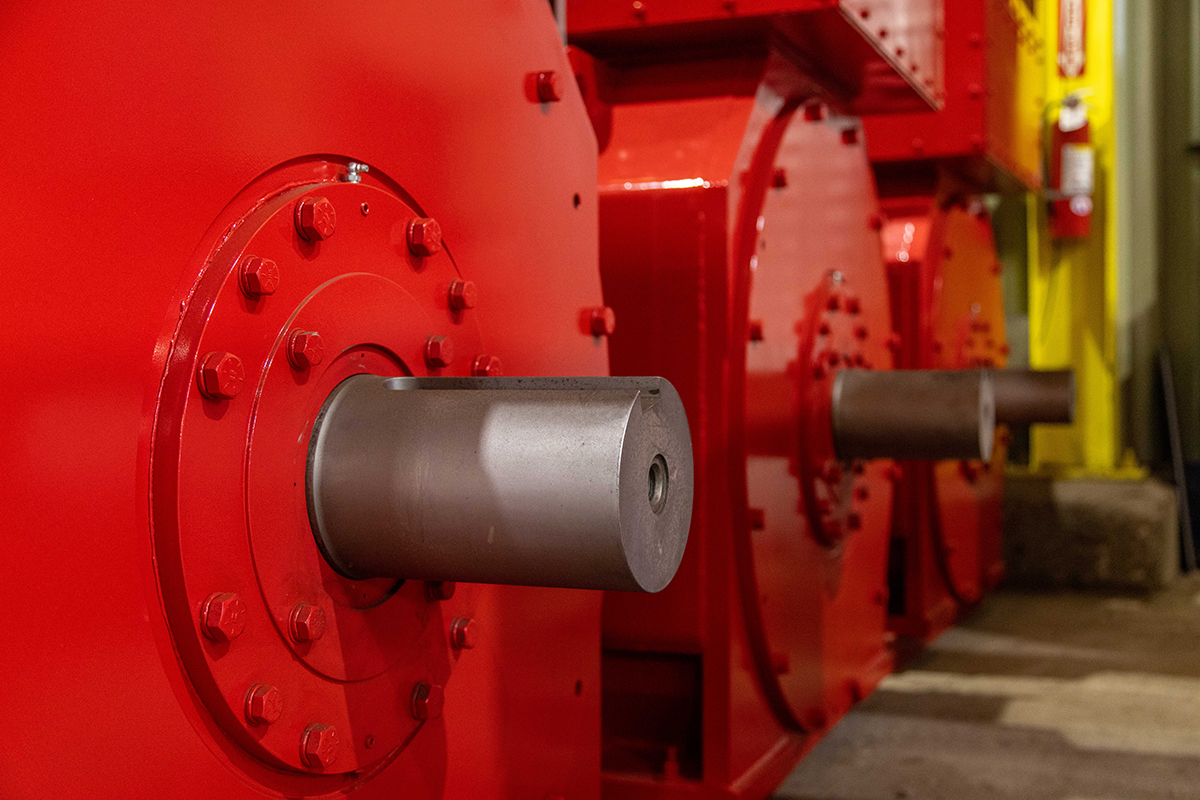

Industrial Service Solutions designs, manufacturers and repairs electric motors for the world’s largest machines and harshest operating conditions. ISS distributes OEM and custom build a complete range of industrial motors – synchronous as well as asynchronous, both AC and DC, from fractional HP to 20,000 HP. UL Listed, ISO-certified service shops provide comprehensive services including teardown, inspection, evaluation, insulation systems, machining, balancing, sheet-metal fabrication, welding, testing, and quality control.

Learn more about Electric Motor Services